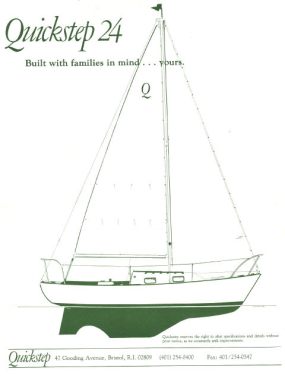

There are many beautiful Q24s sailing about, so it’s only right and proper that we have a page devoted to them. So here we are! If you own a 24, you’re welcome to post. I’m happy to add pictures, too. To post a new comment, you’ll have to scroll to the very bottom of this page- all the way down. I’ve managed to change the formatting to display just the newest comments first, so scrolling down is no longer so tedious. All of the older comments are still here though. Just follow the link at the bottom of this page.

Hello to all! I am selling a Quickstep 24 located in East Boston.

Here is a link to the Craigslist ad:

https://boston.craigslist.org/gbs/boa/d/east-boston-quickstep-24-sailboat/7002965568.html

Fair winds …

Hello, do you still have that boat for sale ?

Hi Patrick: I have a Q24 in RI that I plan to put on the market shortly if you’re in the market. -Chris

Thanks for the quick reply Chris. Would be interested in getting price and details as soon as possible as I am considering another boat this weekend. When do you expect to post it?

Patrick:My email is crunci@runcigroup.com . Please email me your info and I will pull together the info. -Chris

Found some reasonable hull liner replacement sources for anyone considering replacement.

I have seen the Defender material and it is very good. The Miami material appears the same and is spec’d at the same weight.

https://www.miamicorp.com/default.aspx?page=Item%20Search%20Results&SearchFieldsList=Keyword&SearchSource=ProductSearch&txtSearchText=Hull%20liner

https://search.defender.com/?expression=Hull%20liner&s=1

Replaced the hull liner with Sailrite ” Seabrook Sea White” foam backed headliner – no perforations. Color closely matches the Formica. Req. 8 yds 54″ wide at $30 /yard. Can be split down the middle for the 1/4 berths. and 3 cans of 3M General trim spray adhesive at $26 each !. Looks like a Million$ and brightens up the whole cabin. Some noticeable dampness noticed, though, especially in the 1/4 berths. Since the genoa track is suspect, and totally removable, I’ll probably remove it and re-bed in the Spring.

Update on above hull liner. The Defender and Miamicorp products are identical. The sample cards are both Miamicorp logos. Defender sells Miamicorp product. I did my interior with yardage from Miamicorp $13 and change per yd. 72″ wide. Its great. High quality, dense, breathes, easy to work with, and bargain. Interior looks impressive. These Q24s are some sweet little boats!

Here is a maybe helpful thing to consider. I had an area on the port side quarterberth hull lining that had been stained and felt moist lately after rain. Figured it was leaking in from either the winch island , the hull deck screws or the toe rail bolts. All the toe rail bolt bungs were in good shape but underneath where the bolt came through the hull there was some discoloration around a nut and washer. I decided to snug the toe rail nuts. I marked the thread with a sharpie pen and began snugging the nuts being careful not to move the bolt by watching the mark. Got about 3/4 turn on a few and a half on the others fore and aft of the stain. Did not make too tight, call it very snug. Then it rained around here for 2 more days and not a bit of moisture could be felt in the lining material. I’m hoping the moisture was entering the toe rail bolt hole under the toe rail and the caulking there was still serviceable enough to soldier on. By no means a certainty but it is better and may be a worthwhile thing to try before drilling bungs , pulling bolts and re-caulking the toe rail. Anyone with any experience in this area? Thanks

Mine was badly stained in the same area when I purchased the boat a few years ago. I figured the winch pedestal. I tore that portion of the lining out and have never seen water since with all sorts rain conditions?? There are other parts of the lining that are mildewed. That brings me to my next question. Has anyone undertaken the task of replacing the lining.? I’m thinking of automobile headliner.

Ripped the original liner out and replaced with Home Depot indoor/outdoor gray carpeting. Super low pile. Kept the original pieces as templates and chalked it out on the new, with an inch around to trim for error. Steel brushed, scraped and vacuumed as much of the old backing material as I could off the inner hull, but didn’t worry about it too much. Used 3M super adhesive backing. Sprayed and fitted along the top edge of the new liner first, adhered it to the top cabin edge, and let it hang like a curtain. Fitted, trimmed, then lifted from the bottom and sprayed both the new liner and the hull, but lightly. It doesn’t take a lot to keep it in place. The ‘curtain’ technique had the added benefit of containing the adhesive spray, keeping it from getting all over the cabin, woodwork, other surfaces. Best to line up the new liner weave carefully. I aimed for the weave to run horizontally. Looks good. Used a cheap plastic paint scraper to tuck new liner edges under the wood trim of counter/sink top/ bow anchor box, etc. Looks clean, neat, and a lot better than the original. Also, I won’t feel bad if I have to rip it out again someday. Hopefully not, but if so, it won’t be hard to remove, clean, and replace. I liked the idea of horizontal wood interior, but weight, time, maintenance, all that? I like what I have.

Thanks Eric. I DID in fact save the liner in case I needed a template.

Yeah, I thought of the wood slats too.

The ‘curtain’ technique had the added benefit of containing the adhesive spray,

I’m gonna remember that!

Great post Eric lots of good stuff here.

Eric. Took a closer look yesterday and the bottom of the original liner is tucked underneath the plywood covers over the lower compartments. Did you remove these? Its a big job .

I don’t recall. But if it was, I did not remove the boards below the cushions. I’d use a box cutter and lightly score the liner as close as you can there and pull it away. For me, it didn’t matter that the new liner was an inch or two long on the vertical, because it could simply lay on those boards and the cushions go right over them. However, my old liner was not moldy or mildewed. It had just started to fall away after several years of abandonment on the hard. You might be able to just loosen the screws that hold those boards and pull the liner out.

Sailrite sells “hull liner” material, specifically for this purpose. It is similar to the HD/LOWES carpet, but it do NOT have the backing, so it conforms & stretches to the curves. $22/yard, 72″ wide. Works great, have used on multiple boats, and use the same process as others above, i.e. Clean, cut to shape, spray adhesive, press in place, trim.

Hi All

I may be putting my 1989 Quickstep 24 up for sale.

It is located in Winthrop Ma.

The boat is in beautiful shape.

Any recommendations on where to list it.

Thanks

Mark

We are actively seeking a Quickstep 24. Love to hear more (price) details etc.

butchr@shiversurveys.com 252-269-8692

Thanks for your time!

Butch R.

I guess the obvious choices — other than this site — are Yachtworld (if you want to involve a broker) and Craigs List. Please let me know when you do. I have a friend looking for either a 21 or 24. Thanks

Hello All: I have a Q24 I’m interested in selling this summer. She is in Rhode Island. -Chris

Short affair Chris! Movin on up?

Please let me know if the boat is available, I am looking for a Q 24 in New England . Thanks

I think this one is pretty good…https://www.sailboatlistings.com

Also http://www.sailingtexas.com/ctexasclassifieds.html

Not just Texas.

Why are you selling Mark? Bought a Alerion 28 I hope!

Broke up with my sailing partner, not easy to find capable sailors that don’t own a boat themselves.

Thanks for the sites Chris.

Has anyone ever put a bimini cover on their Quickstep 24? Not a lot of room, but shade would make a difference for how my boat is used. If yes, do you have a picture?

Jeff. There’s not enough overhead clearance for a proper bimini with the Main at 100%. I have a fixed boom gooseneck and I’m thinking of replacing it with a sliding gooseneck in the sail track, so that I could employ a bimini with the main reefed. OR replace the main with a new loose footed main with cut down luff by about a foot. I figure the improved sail shape at the foot will compensate for the loss of sail area.

That is my impression as well. It would be a very tight fit, with too many compromises. Was thinking also about raising the boom 8-12″ to accommodate. The loss of sail area is regrettable, but a bimini during the hot summer months on the Chesapeake may make the boat much more pleasant.

Has anyone replaced chain plates on a Q24? Any suggestions for checking them and/or replacing them?

1/4″ welded flat stock is pretty durable unless you really abused it or somehow corroded it . Stainless needs to breathe. Unscrew your 6 deck caps and dig out the sealant and look for pitting / corosion. You can see everything else from above or below.. If yours are ruined, remove them, they bolt through bulkhead under plywood trim and take to a welder for repair or reproduction. I’d bet you are in good shape.

Thanks Chris, this is very helpful. I will remove the caps and check them out as you suggest. Any suggestions for a good sealant?

Thats a good one. 3M 4200 is probably the go to goo here. I tried everything in that area, all the fancy marine products including butyl tape. Currently I use 5$ GE silicone to seal the chainstay caps. The stays are always working as you sail and are prone to leaks. Silicone has proven to move with the boat and remain waterproof. I re-do annually. Totally dry. Some will say silicone has no place on a boat. I agree except for this use. When you remove the caps be aware that some screws may go all the way through the chainstay while others only go into the deck and will probably need to be improved by drilling, removing some balsa under the deck skin then filling w/epoxy mix of your choice. Properly drill tap holes for your screws. Tighten only enough to seat the caps on your sealant of choice. These are not structural. BEWARE, silicone is a problem if you intend to paint. Paint problems WILL occur if you don’t prep meticulously.

You can bend 3/16″ of a finish nail at the tip to a 90deg angle put the nail in a drill and fish it into the screw hole to remove a bit if balsa. Tape your screw holes to keep epoxy off the deck. A trimmed small allen key works as well.

Thanks Chris. I appreciate your advice and experience!

Anybody have the occasion to remove the vee bow water tank? If so , if I cut the aft cross piece out, will it then slide out of the larger aperture behind it? Has anyone found a suitable replace tank?

Morning

Yes I have and yes you can…..

You can have them cleaned,sanitized, or you can do it yourself.

I made the mistake of tossing mine.

I just added a small 9 gallon tank,I still don’t even use that much.

I always have fresh water on board for drinking.

Enjoy

Thanks Larry. I’m going to remove it and try to clean it up myself. Its nasty, slimy and stinks. I think ill have better success cleaning it up if it’s out of the boat. .. Yes, I always carry a gallon or two of bottled water but I’m going on an extended cruise this summer and could use the extra 9 or10 gal. with the weight positioned where it should be.

You could fill with strong bleach solution, shake and use the sink pump to fill hoses. Let sit , pump and flush as needed. If ur boat is on trailer or stands, put a primed hose in tank, out the hatch and down to ground , mine has an access plate of hand hole size for pressure hosing and scrubbing, and use siphon effect to drain fast. I have a hard poly V tank under berths with about 15g cap. Instructions on bleach bottle for water purification too. I don’t trust dock water.

It wasn’t too hard to remove the tank after cutting the cross-bar out. Then power washed , turned upside down, etc.getting all surfaces, then sanitized. By the way, how do you fill the tank? The 1/2 in hose fitting in the front top of the tank appears to go nowhere. Through the access plate?

Yes, I use access hand hole. No deck fill plumbing here. Doesn’t seem worth the effort.

Thanks Chris

Here’s something for all us slaves to varnish. I just stripped my entire tor rail, motor board and gas locket slats in 6 hours. Clean and ready for first coat of varnish. Motor board didn’t even take 10 mins.

Used this scraper with the corners knocked off.

https://www.amazon.com/MANUFORE-Ergonomic-Carbide-Scraper-1-5-Inch/dp/B06XW7H53S/ref=sr_1_14?crid=35ZJVN4VE4R71&keywords=manufore&qid=1554929141&s=gateway&sprefix=Manufore%2Caps%2C165&sr=8-14

Super sharp and not dull yet.

Made some heat shields from aluminum flashing of different radii to protect Awlgrip in my case maybe gel or paint in others. Shields Up!

Virtually no sanding needed and no chemicals either. Am I the last to learn?

Might try the heat gun on the toe rails this year. Problem is you need 3 hands don’t you? One for the heat gun,one for the scraper and one for the heat shield. I swear by my Sandvik scrapers. Thanks for the tip.

Two will do. I shielded my deck a foot at a time with a handheld piece of flashing held in the wood/deck joint. Only have to heat that section for a minute or less until your fingers burn, put the flashing down and scrape with the carbide scraper. My varnish never blistered but got soft and came right off. Works much cleaner than the youtube guy shows with the old fashioned scraper. These carbide scrapers are the best.

Hi Chris

Definitely the way to go. I use the heat gun and scraper method as well. My finish is still gel coat, so I am not as fussy with heat shielding.

Mark

Msg to John D…followup from boatyard question. I’d remove and caulk everything from under the stainless plate on up. Inspect the mast for entry holes and seal them too. Sounds like you may have compression in the cabin top necessitating the stainless plate? Not sure though of course. Consider, if your cabin has no crown but a compression under the mast that water could be entering elsewhere (screw holes, poorly bedded hardware etc) and flowing down into the compressed area resulting in leaks that appear to be mast related but may no be. May have a flooded core again with a river flowing through it. Over tensioning your stays will drive the mast straight down resulting in certain boat death. Boats on moorings rolling in waves need to pay particular attention here. Its a deck stepped thing not a Quickstep specific issue. And now its freezing too.

Just contemplating things now that the boat’s out of the water – my question is – can a QS24 heave to? I’ve been unsuccessful in several attempts. The bow would just blow off the wind each time I back-winded the jib ( furled to about 110%) Is there just too much cutaway in the forefoot?

It works fine Dave. Have appropriate sail up. Tack across the wind but leave jib sheet alone. Jib is on the wrong ( back winded ) side now. Sheet the main till just the leech is filling and push the tiller to lee and lash it. From there its minor tweak’n. Boat will more or less pinch up to the wind but fail to tack…repeatedly and you will be sliding downwind slowly.

Thanks Chris – I’ll experiment some more next season.. need to be able to reef in a blow

Dave P..back in Feb you were talking about boarding ladders. I have come round to thinking of adding one. In one of the seller appeals below is one I was interested in. I’d make the struts foldable but otherwise the design looks simple and clean. I’m wondering what you and others with ladders thought of it. Link below, middle picture of the three is best. Thanks.

http://brooklinboatyard.com/ruby/

Chris, I have been looking for a ladder and agree the one pictured on the Q24 at Brooklin Boat Yard looks ideal. I have been searching the web to identify a similar one online. However, I assume it was custom built. I would be glad to know if anyone has information about the ladder or where one could be custom made.

Thanks Don, Looks good but for the non-hinged standoff legs. Welded standoffs keep ladder from crashing into topsides but look awful. @$100 in tubing and hardware plus bending and welding @10hrs time. Just don’t want to go through the trouble for a bad design. More thought is still needed. Good winter project maybe.

Chris,Don;

Looks like the discontinued Garelick 12048 turned upside down, or the current Garelick with 180deg U bend cut down to 90deg. Then possibly fitted with a swivel pad, such as used for Bimini tubing. A good idea. The problem with the pictured arrangement is that the topsides are high in that position and curvy and probably wont sit squarely against the hull. My setup uses the 12048 with pins mated to receiver plates just forward of the winch pedestals at the lowest point of the sheer. The ladder is easily stowed in the port locker. I customized the standoff legs using PVC pipe to fit the curvature of the hull. There is no problem with the standoff legs collapsing.

Dave

Thanks Dave, sadly the operative word is ‘discontinued’. I would think the curve of the toe rail fairly closely matches the hulls curve and plan to mount mine somewhat forward as yours is. My Q has no stern pulpit. Maybe one standoff would need to be a bit longer than the other. I’m starting to collect parts for my ladder, Ebay, direct from China. MAGA. I will keep you posted. Thanks

BTW…What is the model of the ladder you refer to as current the 06131 or original 05041? I’m not against adapting but these are aluminum I think.

Neither. The one I thought I was referring to seems to have disappeared from the Garelick site. Garelick had sent me the production drawing and parts list, of the 12048 – I can e-mail it to you.

Got your PDF Thank you.

Chris. Moved permanent SS boarding ladder, deployable from the water, back to the top of the list for Spring project. Friend of mine (here in Florida) fell off his catboat couldn’t get back in for an hour and suffered severe hypothermia (at 67DegF water temp!). Probably will be a custom design using an existing product as a starting point. Let me know how your design is developing.

https://www.amazon.com/gp/aw/d/B00FX32RYQ/ref=psdcmw_3398641_t3_B0000AZ7KC

Dave, what do you think of this for a starting point. Looks adaptable. Very similar to the Garelick 12408.

Another that looks workable

https://www.amazon.com/Pactrade-Marine-Foldable-Stainless-Ladder/dp/B00KN4M90C/ref=pd_aw_sbs_200_of_28?_encoding=UTF8&pd_rd_i=B00KN4M90C&pd_rd_r=552c8812-1c25-11e9-8ebd-0d418ae6b851&pd_rd_w=nr9Gd&pd_rd_wg=PUJ9u&pf_rd_p=926ebe02-3236-40c6-ac63-01ad178f498a&pf_rd_r=VVNS96P2D58NGXW33HSS&psc=1&refRID=6SR5R3RFAVY5V3B5CW6Z

See similar items on amazon

Or this Whitewater…look to be better quality.

https://www.amazon.com/gp/aw/d/B00FJI2542/ref=sspa_mw_detail_3?ie=UTF8&psc=1#immersive-view_1548015504713

Chris. You did some nice research with a few more possibilities. Probably the Pactrade Marine. It appears fairly long. To get the ladder to pivot vertically 180deg you’d pribably have to add a 2” block of plastic to raise the base fitting allowing the bend to clear the deck. Also the standoff struts seem a little low. These could be placed higher and set up to “fold” as they would be fairly lengthy. But would need to get actual dimensions and lay it out before making final decision on any of them.